Spindle Repair for every brand & size

High quality service

Since 1966.

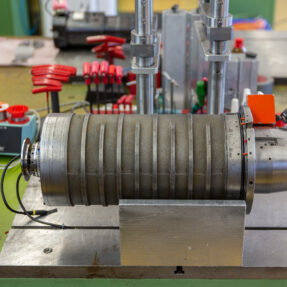

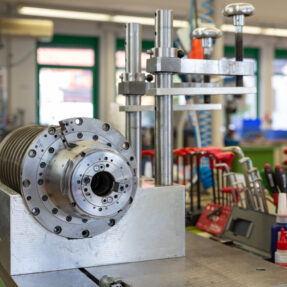

Thanks to the decades of experience of our employees, special training with various spindle manufacturers and our own spindle construction department, we can repair all spindles – motor spindles or externally driven spindles. The active supplier relationships with manufacturers of clamping systems, bearings, rotary joints and seals allow us to obtain original parts in a short time. Spindle-specific components can be calculated, designed and created by PTC‘s 3D CAD system as needed (shafts, rings, flanges, etc.). Flexible suppliers and in-house manufacturing enable timely production of the highest quality.

Spindles from 1kg to 1,5t

We repair all brands and sizes. Do not hesitate to contact us today!

There are no hopeless cases for us!

You receive professional repair and exchange spindles service on spindle units of all common makes and machine manufacturers.

We repair spindles of machine manufacturers Deckel Maho, DMGMORI, DMG, Gildemeister, Mitsubishi, MAKINO, Matsuura, FANUC, FAMUP, FAMAR, Hermle, Voumard, Jung, Mikron, Vollmer, Huron, Forest, Chiron, Okuma, EIMA, Quaser, Röders, Hurco, Weeke, HOMAG, IMA, Fadal, UVA, Lidköping, Bridgeport, Starrag Heckerth, Brother, Hardinge, AXA, Datron, KaoMing, Kafo, Portatec, Kern Microtechnik, HitachiSeiki, MAG CorCom, Mazak, Haas, SHW, Alfing Kessler, EMAG, FFG, Meccanodora, NOVA, Alzmetall, Doosan, Breton, MtRent, Weisser ABB, Benzinger, Schaudt Mikrosa, SCHERER, Studer (Schleifring Group), TRAUB and many others.

We repair spindles made Franz Kessler, Voumard, Fischer, Weisser, Benz, Omlat, GMN, GF Georg Fischer, FAMAR, FAMUP, Fortuna, Renaud, Precise, Reckerth, KaVo, Perske, Jäger, IBAG, Heller, Hauser, Gamfior, Faemat, FAG, Bryant, Colombo, Deuschle, Diebold, Walther, ELTE, Hiteco, Blohm, SKF, SMZ, Weiss, Junker, UVA, TDM, HSD, SCHERER, StepTec, Setco, UKF, DMGMORI, DMG, IMT, Jung, Royal, AWEA, Quaser, Schaudt, Studer, Spinder, Mitsubishi, Myl, TRAUB, Haozhi and many others.

As part of the disassembling and analysis of a spindle repair all components such as bearing flanges, housings, spindle shafts and shaft taper adapters (HSK, BT/ISO, etc.) are measured accurately.

For this purpose, ZEISS & MAHR metrology machines are available in order to be able to determine seat and geometry errors with the highest measuring accuracy.

All damages such as worn-out bearing seats, defective clamping systems, leaking cylinders and rotary joints can be repaired or exchanged to new. Extensive machinery with CNC grinding, milling and turning machines is available in-house. Thus, the delivery times can be influenced and express repairs can be realized asap. The result of the individual measures corresponds to the quality and accuracy of the original condition.

Thanks to the new spindle manufacuring we know the required tolerances for those spindle types.

References

Meanwhile, about 900 spindles of all sizes and types are repaired by us yearly.